Hew's Wire Coiler

There are any number of maille web sites that show you how to make a mandrel for coiling wire into springs to make rings, but when it comes to making the coils, you'll find that the hand that feeds the the wire onto it has to both pull the wire tight and allow it to slip through the fingers. Even with gloves (and maybe a little thimble-like plate attached to the thumb of the glove) my fingers get tired and sore before I get half-way along. So, I made a gizmo that does the job for me. It does a pretty good job of straightening out bends in the wire too.

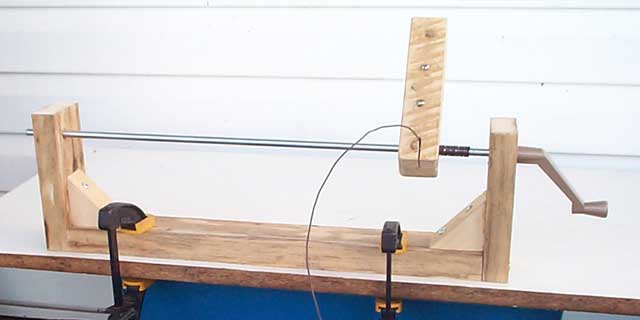

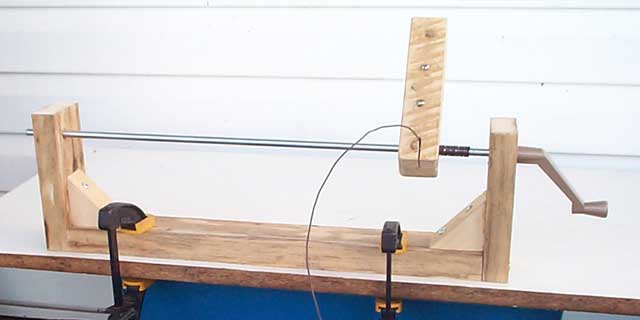

My mandrel base is set up for a 21" long 5/16" diameter steel rod, a leftover piece from the axle of a trebuchet. The handle is a generic replacement window crank from a local Home Hardware store. To make the crank fit I had to turn the end of the 5/16" rod down to 1/4 inch diameter, on a metal lathe. I slightly flattened one side with a grinder, for the setscrew on the side of the handle. I could have drilled out the handle to 5/16", but I wanted to keep it so I could still use it on a 1/4" rod someday later. I could also simply have bent the rod into a handle, but this way I get to use the extra 6 or 8 inches for longer coils. A removeable crank handle also gives me the option of power-winding with a variable-speed electric drill

The support is some really cheap 1" x 3" scraps I found under my porch. The angled braces are screwed down with two 1 3/4" wood screws each, and the end pieces are screwed into the end grain of the bottom board with two screws each.

The winding tool is two scraps of some kind of 1"x2" hardwood (maybe oak?).

Cut two identical lengths, clamp them together, and drill them in two spots with 1/4" holes, closer to the centre, for the 1/4" bolts.

After bolting them together, drill all the way the sides with a 5/16" bit (for a 5/16" coil forming rod). They must be tightly bolted together when you do this, or the two wood pieces may slide over each other as you drill, resulting in hole halves that don't line up.

Turn it over, and drill only half way through the 5/16" hole with a 7/16" bit (for 16 gauge wire), so that the hole is larger on one end than on the other.

Take one of the pieces, and saw a slot in the end, stopping at the inner side of the 7/16" portion of the hole.

(The photo below is a bit misleading because the angle I took it at makes it look like I sawed it only to the inner side of the 5/16" hole.)

I chose this half because I'm right-handed, and I wanted to turn the crank clockwise, feed the wire from the front of the mandrel, and have the coils to come out with a twist that has the opposite handedness from that of the threads on screws and bolts. That way, when I use my snips (also right-handed) to cut the rings I can see the end of the coil butt up against the upper jaw of the snips. If I was left-handed and used left-handed snips, then I would have cut the slot in the other half of the tool.

Notice the grooves in the wider hole. These were formed when I first used it to wind wire, and result in a gap of about 1/3 the diameter of the wire between each turn. I haven't tried it, but I'm pretty sure that if you cut the slot at a slight angle, that gap would be a bit bigger.

I could have just drilled a 1/16" diameter hole, but that would mean I'd have to disassemble the tool every time I wanted to start a new coil. The slot allows me to find the hole in the rod when I insert the wire end, and then give it a 1/4 turn to lock it in.

Here's a closeup of the bending tool in action. I hold the tool in my left hand to keep it upright, and crank the mandrel with my right. The spool of wire feeds up from the floor, to my left. If I had a stand for the wire spool to roll freely, I could just put it on the bench behind the mandrel, and just let the free end of the tool slide along the mandrel base.

As the coil gets near the left end of the mandrel (one full width of the tool between the tool and the left rod support) , I just snip the wire and allow the end to feed in, and crank it until the last turn clears the right side of the tool. I pry the other end of the wire out of the hole in the rod and snip it, allowing me to pull the rod out of the support and remove the coil. This setup only wastes about 1/2 of a ring's worth of wire per coil.

Even without the wooden base for the mandrel and crank, you can simply use vise grips to turn the rod, and hold the bending tool with the other hand.

Of course, after I made this wooden tool, I discovered that Matthew E. Johnston describes a tool with a similar function, at http://members.tripod.com/~mailmaker/tools.html. He also shows how to make two other kinds, at http://members.tripod.com/~mailmaker/winding.html .

Hew of Kilraag (mka:John Rose)

Over to my Hew of Kilraag - Medieval Stuff index page