New Improved Pouch

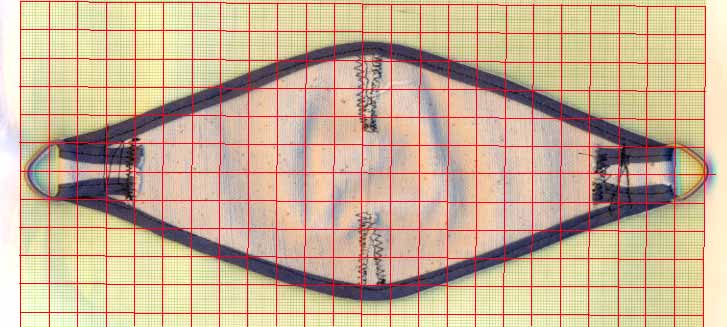

Scan scaled to 100% of actual size. The red lines represent a 1 centimeter grid.

Scan scaled to 100% of actual size. The red lines represent a 1 centimeter grid.

I folded the edges of the canvas over and sewed it with a wide hem (or whatever you might call it) so that I could pull the cord through it like a drawstring. (What you see here is not the sling as such - it's just the loops that the sling lines tie to.) I broke three #16 sewing machine needles to make this, mostly where the edges are gathered and folded to make the curves. The canvas itself was kindly donated by my wife, who paints.

My intention was to make it easy to centre the pouch on the sling when I was tuning it. Instead of changing the length of both sling lines (which were tied to the two loops), I merely had to change one and then reposition the pouch to the centre.

It seemed like a good idea at the time, and it was easy to centre the pouch. However, it didn't perform very well. It was difficult to control the release timing. It kept spiking the ball a few feet in front, and I had to keep shortening the sling (down to about 75% of the throwing arm length) and straightening the release pin (to something like 10 or 15 degrees). I eventually was able to hurl a tennis ball about 25 meters, but when I tried a denser payload (rock the size of a walnut) it often failed to leave the pouch at all, just hitting the ground *whap* in front of the treb.

I guessed that the pouch had too much concavity to it, especially while under tension. A dense payload like a rock made it worse as the edges pulled tight, like a drawstring. It probably would only work well with over-sized payloads that hung out over the edges, like canned goods, or maybe softballs.

I folded the edges of the canvas over and sewed it with a wide hem (or whatever you might call it) so that I could pull the cord through it like a drawstring. (What you see here is not the sling as such - it's just the loops that the sling lines tie to.) I broke three #16 sewing machine needles to make this, mostly where the edges are gathered and folded to make the curves. The canvas itself was kindly donated by my wife, who paints.

My intention was to make it easy to centre the pouch on the sling when I was tuning it. Instead of changing the length of both sling lines (which were tied to the two loops), I merely had to change one and then reposition the pouch to the centre.

It seemed like a good idea at the time, and it was easy to centre the pouch. However, it didn't perform very well. It was difficult to control the release timing. It kept spiking the ball a few feet in front, and I had to keep shortening the sling (down to about 75% of the throwing arm length) and straightening the release pin (to something like 10 or 15 degrees). I eventually was able to hurl a tennis ball about 25 meters, but when I tried a denser payload (rock the size of a walnut) it often failed to leave the pouch at all, just hitting the ground *whap* in front of the treb.

I guessed that the pouch had too much concavity to it, especially while under tension. A dense payload like a rock made it worse as the edges pulled tight, like a drawstring. It probably would only work well with over-sized payloads that hung out over the edges, like canned goods, or maybe softballs.

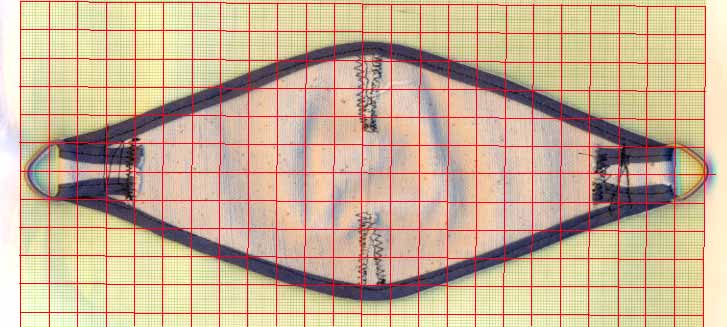

Scan scaled to 100% of actual size. The red lines represent a 1 centimeter grid.

Scan scaled to 100% of actual size. The red lines represent a 1 centimeter grid.

It was a bit deeper than I planned on, but it seemed to work fairly well anyway. My ranges improved by about 20% and the grouping of the hits was smaller. The payload always left the pouch.

New pouch in launch trough, loaded with a road hockey ball:

It was a bit deeper than I planned on, but it seemed to work fairly well anyway. My ranges improved by about 20% and the grouping of the hits was smaller. The payload always left the pouch.

New pouch in launch trough, loaded with a road hockey ball: