Foehammer

Mini-onager (grape class)

This one was built as a birthday present for my son. Cameron Rose. He chose the name "Foehammer".

| base | 220 x 114 mm |

8" x 4 1/8" |

| backstop height | 154 mm | 6" |

| base timbers thickness | 20 mm | 3/4" |

| scutula (long base timbers) height max | 45 mm | 1 3/4" |

| base ends height | 36 mm | 1 3/8" |

| backstop uprights thickness | 12 x 25 mm | 11/16" x 1" |

| throwing arm length | 204 mm | 8" |

| pin length (beyond arm tip) | 7.5 mm | 5/16" |

| sling to bottom of pouch length (from pin) | 70 mm | 2 3/4" |

| range (3/4" wooden bead) |

max 16 m average 12 m |

54 feet 40 feet |

| Wood | maple, finished only with carnauba paste wax | |

| Pouch (with three-point sling) | calfskin split leather, dyed yellow. It was a sample swatch from a jacket manufacturer. I should have used something thinner and limper. | |

| Sling and lashing | hemp twine | |

| Backstop bumper | maple "plank" covered with foam rubber and leather. | |

Most of the assembly used small brass screws, except for some white carpenters' glue on the knots, the black leather backstop pad cover, and the pouch.

The double sling hitch loops lashed to the arm is just a length of 14 gauge annealed steel wire, wrapped 1 3/4 times around the arm.

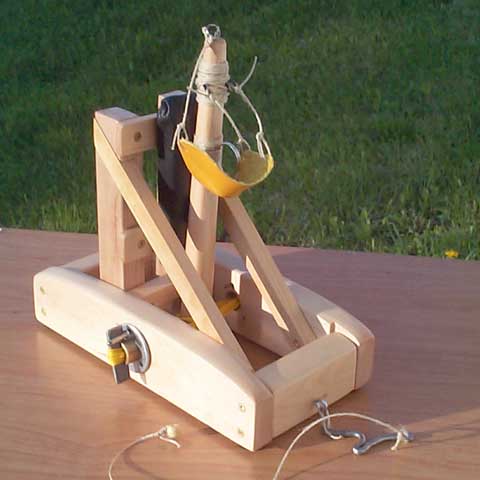

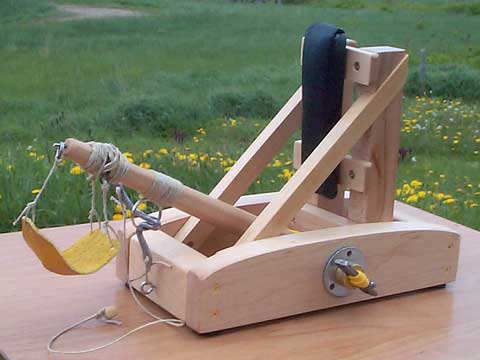

Set up for firing, waiting for the ammunition. The release pin is a small headless finish nail, pushed into a hole drilled into the arm tip.

Note the "sliphook" trigger, based on an illustation in Payne-Gallwey's book, The Crossbow. (see reference below) I made this one from a nail, flattening the ends with a hammer and anvil - just like in the good ol' days.

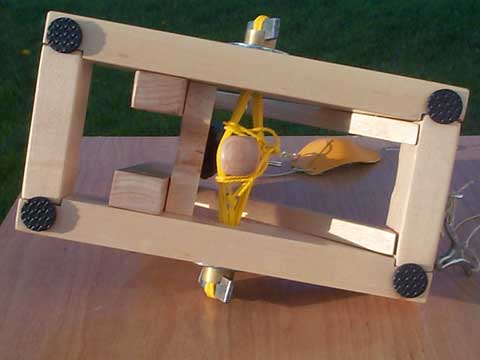

Bottom view.

The throwing arm has a bit of a knob on the bottom, to prevent it from falling

out of the torsion skein (or torsion bundle). I got this idea from the

Payne-Gallwey book as well. The rest of the arm has a rounded-square cross-section,

tapering to a circular tip at the pin end.

Note also the semi-circular indentation in the bottom of the cross-bar, which

makes room for the bottom of the throwing arm when it's cocked.

The black dots are vinyl rubber stick-on pads to prevent slippage when fired

from a smooth surface.

|

Modiolus, epizygis, and skein tunnel parts. The brass parts (16 mm diam) were turned on a lathe and then notched with a file. I ground the centre of each epizygis (rectangular bar) to a wedge-shaped cross-section so as to allow more room for the torsion bundle as the loops entered the brass tunnel tube. The pins are pop-rivets. They get inserted through one of the holes in the modiolus after pre-twisting the bundle, preventing the epizygis from slipping. The modioli are simply a pair of steel washers, drilled with three holes. |

|

Closeup of modiolus and epizygis. I was able to get 7 turns of polyested twine in the bundle. To do that, I had to use a loop of thin wire stripped out of a twist-tie, and pull the twine loops through. The small holes in the modiolus goes right through the scutula (wooden side beam). Having three of them gives six possible positions that the epizygis may be turned to. |

Inspirations for this design:

More siege engines at Hew's Medieval Stuff index page.